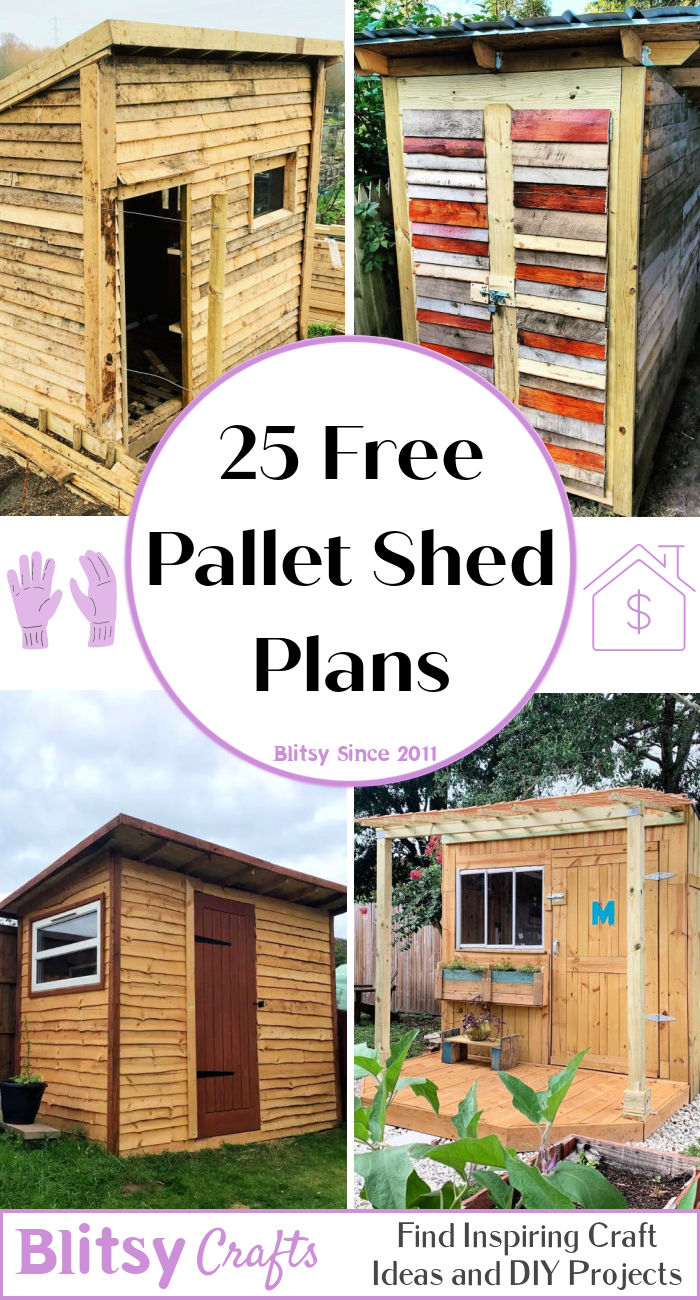

DIY Pallet Shed Plans: Create a Budget-Friendly Storage Solution

The escalating costs of pre-fabricated storage solutions often leave homeowners seeking more economical alternatives. A compelling and practical solution lies in the repurposing of readily available and cost-effective materials: reclaimed wooden pallets. This comprehensive guide provides detailed plans for constructing a durable and aesthetically pleasing pallet shed, offering a budget-friendly storage solution for various needs.

I. Planning and Preparation: Laying the Foundation for Success

Before embarking on the construction process, meticulous planning is crucial for ensuring the project's success. This initial phase encompasses several key steps designed to optimize efficiency and minimize potential complications.

A. Assessing Your Needs and Site Selection:

The first step involves a thorough assessment of your storage requirements. Determine the dimensions of the shed based on the volume of items you intend to store. Consider factors such as the height needed to accommodate taller objects and the desired floor space for easy navigation. Once the dimensions are established, select a suitable location on your property. The chosen site should be level, accessible, and comply with any local building regulations or homeowner association guidelines. Proper drainage is also crucial to prevent water damage to the shed's structure and contents. Ensure the site allows for sufficient sunlight and ventilation, especially if storing items sensitive to moisture or temperature fluctuations.

B. Gathering Materials and Tools:

Sourcing high-quality reclaimed pallets is paramount. Inspect each pallet carefully for rot, damage, or infestation. Prioritize pallets made from robust hardwood for enhanced durability. In addition to pallets, you will require various other materials, including:

- Foundation materials: Concrete blocks, gravel, or a treated timber base are all viable options, depending on the soil conditions and your budget.

- Roofing materials: Consider using corrugated metal sheeting, asphalt shingles, or even recycled materials like tarps (for a temporary structure). Ensure the chosen roofing material is weather-resistant and adequately sized to cover the shed's roof area.

- Fasteners: Galvanized nails, screws, and bolts appropriate for the wood type are essential. Choose exterior-grade fasteners designed to withstand the elements.

- Wood sealant and paint (optional): Applying a wood sealant will protect the pallets from moisture damage, significantly extending their lifespan. Paint can enhance the shed's aesthetics and further protect the wood.

- Other necessary tools: A hammer, saw (circular saw or hand saw), screwdriver, measuring tape, level, safety glasses, work gloves, and potentially a drill are all necessary tools for this project.

C. Preparing the Pallets:

Before construction begins, prepare the reclaimed pallets. This includes cleaning them thoroughly to remove debris, dirt, and any loose nails or splinters. Inspect each pallet for any signs of rot or structural weakness. Damaged sections should be repaired or replaced with sound timber. Consider disassembling some pallets to obtain individual boards for specific construction elements or repairs. Sanding down any rough edges or splinters is recommended for safety and aesthetic improvement. Treating the wood with a suitable wood preservative and applying a waterproof sealant before construction will significantly enhance the shed's longevity and weather resistance.

II. Construction: Building Your Pallet Shed

With the planning complete and materials prepared, you can proceed with the construction of your pallet shed. This section outlines the step-by-step process.

A. Building the Foundation:

The foundation is crucial for the stability and longevity of your shed. Several options exist, each with its own advantages and disadvantages. A simple and cost-effective option is a gravel base, followed by a layer of compacted earth. Alternatively, concrete blocks can create a more robust and level foundation. For a more permanent solution, a treated timber frame can be laid as a base. Ensure the foundation is level and large enough to accommodate the planned dimensions of the shed. Proper drainage should be incorporated to prevent water accumulation around the foundation.

B. Assembling the Walls:

The walls of the shed are constructed by carefully arranging and securing the pallets. Start by creating the frame using sturdy pallets. Ensure the pallets are aligned vertically and tightly fitted together. Use galvanized nails or screws to secure the pallets to each other, creating a strong and rigid wall structure. Consider bracing the walls for additional structural support, especially if constructing a taller shed. Repeat this process for all four walls of the shed. Vertical placement of pallets allows for better ventilation and reduces the risk of water pooling within the structure.

C. Constructing the Roof:

The roof design depends on your chosen roofing material and the overall aesthetics you desire. A simple gable roof is often the easiest to construct. The roof frame can be built using additional pallets or timber, creating a sturdy framework to support the roofing material. Ensure the roof has sufficient slope to allow for proper water runoff. Securely attach your chosen roofing material to the framework, ensuring it is weathertight and adequately covers the entire roof area. Consider adding extra reinforcement to the roof structure for regions prone to strong winds or heavy snowfall.

D. Adding a Door and Finishing Touches:

Create a doorway by removing sections of pallets or constructing a frame using additional timber. Hang a sturdy door using hinges and appropriate locking mechanisms. Consider adding windows for ventilation and improved natural light. Once the main structure is complete, finish by applying a wood sealant and paint (optional). This will protect the wood from moisture damage and enhance the overall aesthetics of the shed. Any gaps or cracks should be sealed appropriately to prevent drafts and ensure weather tightness.

III. Safety and Maintenance: Ensuring Longevity and Safe Usage

Throughout the construction process, safety should be prioritized. Always wear safety glasses and work gloves. Use caution when handling power tools, and ensure proper ventilation when working with wood preservatives and paints. Regular maintenance is essential to preserve the longevity of your pallet shed. Regularly inspect the structure for any signs of damage or deterioration. Address any issues promptly to prevent further damage. Periodically clean the shed to remove debris and prevent pest infestation. Re-apply wood sealant as needed to maintain its protection against moisture damage.

By following these detailed plans, you can create a robust and aesthetically pleasing pallet shed, providing a cost-effective and practical storage solution for your property. Remember to prioritize safety and maintain your shed regularly to maximize its lifespan and functionality.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.